Step into the future of textiles with High-performance fabrics 2025, where cutting-edge innovations, diverse applications, and market trends collide to shape the industry landscape. Get ready to explore the exciting world of high-performance fabrics like never before.

Introduction to High-performance Fabrics 2025

High-performance fabrics play a crucial role in the textile industry, offering advanced properties such as durability, breathability, water resistance, and UV protection. These fabrics are designed to meet the demanding requirements of various applications, including sports and outdoor apparel, military gear, medical textiles, and automotive interiors. As technology continues to advance, the evolution of high-performance fabrics has been remarkable, with constant innovation leading to enhanced performance and sustainability.

Evolution of High-performance Fabrics

Over the years, high-performance fabrics have undergone significant advancements, driven by the need for functional and versatile textiles. From the development of synthetic fibers like polyester and nylon to the introduction of specialized finishes and coatings, the evolution of high-performance fabrics has been marked by continuous research and innovation. By 2025, we can expect to see further improvements in fabric technology, including the integration of smart textiles and sustainable materials to meet the growing demands of consumers and industries.

Forecasted Trends by 2025

- Increased demand for sustainable high-performance fabrics, driven by environmental concerns and regulations.

- Growth in the use of smart textiles with embedded sensors for monitoring health and performance.

- Expansion of high-performance fabrics in the athleisure market, combining style and functionality.

- Advancements in nanotechnology leading to fabrics with enhanced properties like stain resistance and antimicrobial features.

- Collaboration between textile manufacturers and tech companies to develop innovative fabrics for diverse applications.

Key Drivers Influencing Growth

- Rising awareness about the benefits of high-performance fabrics in various industries.

- Increasing demand for performance-driven apparel and gear in sports and outdoor activities.

- Technological advancements enabling the production of advanced textile materials.

- Growing focus on sustainability and eco-friendly practices driving the adoption of green textiles.

- Shift towards customization and personalization in textile products, leading to the development of unique fabric solutions.

Technological Advancements in High-performance Fabrics

From traditional fabric manufacturing methods to cutting-edge technologies like nanotechnology and 3D printing, the production of high-performance fabrics has seen significant advancements in recent years. These innovations have revolutionized the industry, leading to fabrics that offer superior performance, durability, and sustainability.

Nanotechnology in Fabric Production

Nanotechnology has transformed the way high-performance fabrics are manufactured. By manipulating materials at the nanoscale, researchers and manufacturers can create fabrics with enhanced properties such as water resistance, stain resistance, and UV protection. Nanotechnology also allows for the development of fabrics that are lightweight, breathable, and highly flexible, making them ideal for a wide range of applications.

3D Printing in Fabric Design

The use of 3D printing technology has opened up new possibilities in fabric design and production. This innovative approach allows for the creation of complex fabric structures that were previously impossible to achieve using traditional methods. 3D printing enables designers to customize fabrics with unique patterns, textures, and functionalities, leading to the development of highly specialized and personalized high-performance fabrics.

Sustainable Practices in Fabric Manufacturing

As the demand for sustainable products continues to grow, the textile industry has been making strides towards integrating eco-friendly practices into the production of high-performance fabrics. From using recycled materials to implementing water-saving processes, manufacturers are increasingly focusing on reducing their environmental impact. Sustainable fabric production not only benefits the planet but also enhances the quality and performance of the fabrics themselves, creating a win-win situation for both consumers and the environment.

Applications of High-performance Fabrics in Various Industries

High-performance fabrics have become essential in various industries due to their unique properties and capabilities. These fabrics are not only lightweight and breathable but also offer exceptional durability and protection, making them ideal for a wide range of applications.

Sports Industry

High-performance fabrics have revolutionized the sports industry by enhancing the performance and comfort of athletes. These fabrics are used in sportswear to improve moisture management, reduce friction, and enhance flexibility. For example, compression garments made from high-performance fabrics help improve blood circulation and muscle recovery, leading to better athletic performance.

Healthcare Sector

In the healthcare sector, high-performance fabrics are used in medical textiles to create advanced wound dressings, compression garments, and surgical drapes. These fabrics offer antimicrobial properties, breathability, and moisture-wicking capabilities, making them ideal for promoting healing and preventing infections. High-performance fabrics are also used in wearable health monitoring devices to provide accurate real-time data for patients.

Military and Defense

High-performance fabrics play a crucial role in military and defense applications by providing protective gear for soldiers and law enforcement personnel. These fabrics are used in ballistic vests, combat uniforms, and tactical gear to provide protection against ballistic threats, chemical agents, and extreme weather conditions. High-performance fabrics are continuously evolving to meet the demanding requirements of modern warfare.

Aerospace Industry

The aerospace industry utilizes high-performance fabrics for various applications, including aircraft interiors, space suits, and parachute systems. These fabrics are lightweight, flame-resistant, and durable, making them suitable for use in extreme aerospace environments. High-performance fabrics are essential for ensuring the safety and comfort of astronauts and passengers during space missions.

Future Applications

By 2025, high-performance fabrics are expected to find new applications in emerging industries such as smart textiles, wearable technology, and sustainable fashion. These fabrics will be integrated with sensors, actuators, and energy harvesting technologies to create innovative products that enhance human performance and well-being. The future of high-performance fabrics is full of possibilities, promising exciting advancements in various industries.

Market Analysis and Growth Opportunities

The high-performance fabrics industry is experiencing significant growth, driven by the increasing demand for advanced materials in various sectors. Key players in the market include companies like DuPont, Teijin, Toray Industries, and W. L. Gore & Associates. These companies hold a significant market share and are constantly innovating to stay ahead in the competitive landscape.

Emerging Trends and Opportunities

- Rising demand for sustainable and eco-friendly high-performance fabrics, leading to the development of bio-based materials.

- Growth in the sports and athleisure market, driving the need for fabrics with moisture-wicking, UV protection, and odor control properties.

- Increasing adoption of smart textiles with embedded sensors for applications in healthcare, military, and sports industries.

- Expansion of the automotive industry, creating opportunities for high-performance fabrics in vehicle interiors for enhanced comfort and safety.

Challenges and Strategies

- High cost of production and limited availability of raw materials pose challenges for market growth. Companies can explore partnerships with suppliers to secure a stable supply chain.

- Regulatory hurdles related to chemical usage and environmental impact require industry players to invest in research and development of sustainable manufacturing processes.

- Competition from low-cost alternatives in the market calls for differentiation through product innovation and customization to meet evolving consumer demands.

- Global economic uncertainties and trade tensions may impact the market dynamics, necessitating a proactive approach to mitigate risks and capitalize on emerging opportunities.

Sustainability and Environmental Impact

In recent years, the focus on sustainability and reducing environmental impact has become a top priority for high-performance fabric manufacturers. With the increasing awareness of climate change and the need for eco-friendly practices, the industry is making significant strides towards adopting sustainable practices.

Efforts towards Recycling and Upcycling

One of the key initiatives taken by high-performance fabric manufacturers is the incorporation of recycling and upcycling processes in their production. By utilizing recycled materials such as PET bottles or discarded fabrics, manufacturers are able to reduce waste and minimize the use of virgin resources. This not only helps in conserving natural resources but also reduces the carbon footprint of the production process.

Use of Eco-friendly Materials

Another important aspect of sustainability in high-performance fabrics is the use of eco-friendly materials such as organic cotton, bamboo, or recycled polyester. These materials are biodegradable, non-toxic, and reduce the environmental impact compared to traditional synthetic fibers. By opting for these eco-friendly alternatives, manufacturers are contributing to a greener and more sustainable future.

Role of Consumers in Driving Demand

Consumers play a crucial role in driving the demand for sustainable high-performance fabrics in the market by 2025. With the increasing awareness and concern for environmental issues, consumers are becoming more conscious of their purchasing choices. They are actively seeking out products that are environmentally friendly, ethically produced, and sustainable. As a result, the demand for high-performance fabrics that are eco-friendly and sustainable is expected to rise significantly in the coming years.

Textiles and Nonwovens

Textiles and nonwovens are two distinct categories of materials used in the production of high-performance fabrics. While textiles are traditionally woven or knitted fabrics, nonwovens are engineered fabrics made through various processes such as bonding, felting, or spinning.

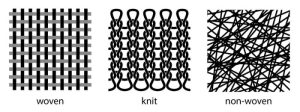

Difference Between Textiles and Nonwovens

Textiles are created by weaving or knitting yarns together, forming a structured fabric with distinct patterns. On the other hand, nonwovens are made by bonding fibers together through mechanical, chemical, or thermal processes, resulting in a fabric without a specific weave pattern.

Unique Characteristics of Nonwovens

Nonwovens possess several unique characteristics that make them suitable for high-performance applications. These include:

- High strength and durability

- Ability to be produced in different weights and thicknesses

- Good liquid repellency and breathability

- Flexibility in design and customization

Advantages and Disadvantages of Textiles vs Nonwovens

When it comes to producing high-performance fabrics, both textiles and nonwovens have their own set of advantages and disadvantages:

- Advantages of Textiles:

- Well-established manufacturing processes

- Wide range of fabric options for different applications

- Good drape and aesthetic appeal

- Disadvantages of Textiles:

- May have lower strength compared to nonwovens

- Less customizable in terms of properties

- May require additional finishing processes for certain functionalities

- Advantages of Nonwovens:

- Higher strength and durability

- Can be produced in a more cost-effective manner

- Excellent barrier properties

- Disadvantages of Nonwovens:

- May lack the aesthetic appeal of woven textiles

- Less breathable compared to some woven fabrics

- Can be limited in terms of design options

Outcome Summary

As we conclude our journey through High-performance fabrics 2025, it’s evident that the textile industry is on the brink of a revolutionary transformation. With advancements in technology, sustainability practices, and market growth opportunities, the future looks bright for high-performance fabrics. Stay tuned for an exciting ride ahead!

Question & Answer Hub

What are some key drivers influencing the growth of high-performance fabrics market by 2025?

The key drivers include technological advancements, increased demand for performance wear, and the integration of sustainable practices in fabric production.

How are high-performance fabrics being used in the aerospace industry?

High-performance fabrics are utilized in aerospace for applications such as lightweight materials for aircraft components and protective gear for astronauts.

What are the emerging trends in the high-performance fabrics market?

Emerging trends include the use of nanotechnology in fabric production, growing demand for eco-friendly materials, and customization of high-performance fabrics for specific industries.